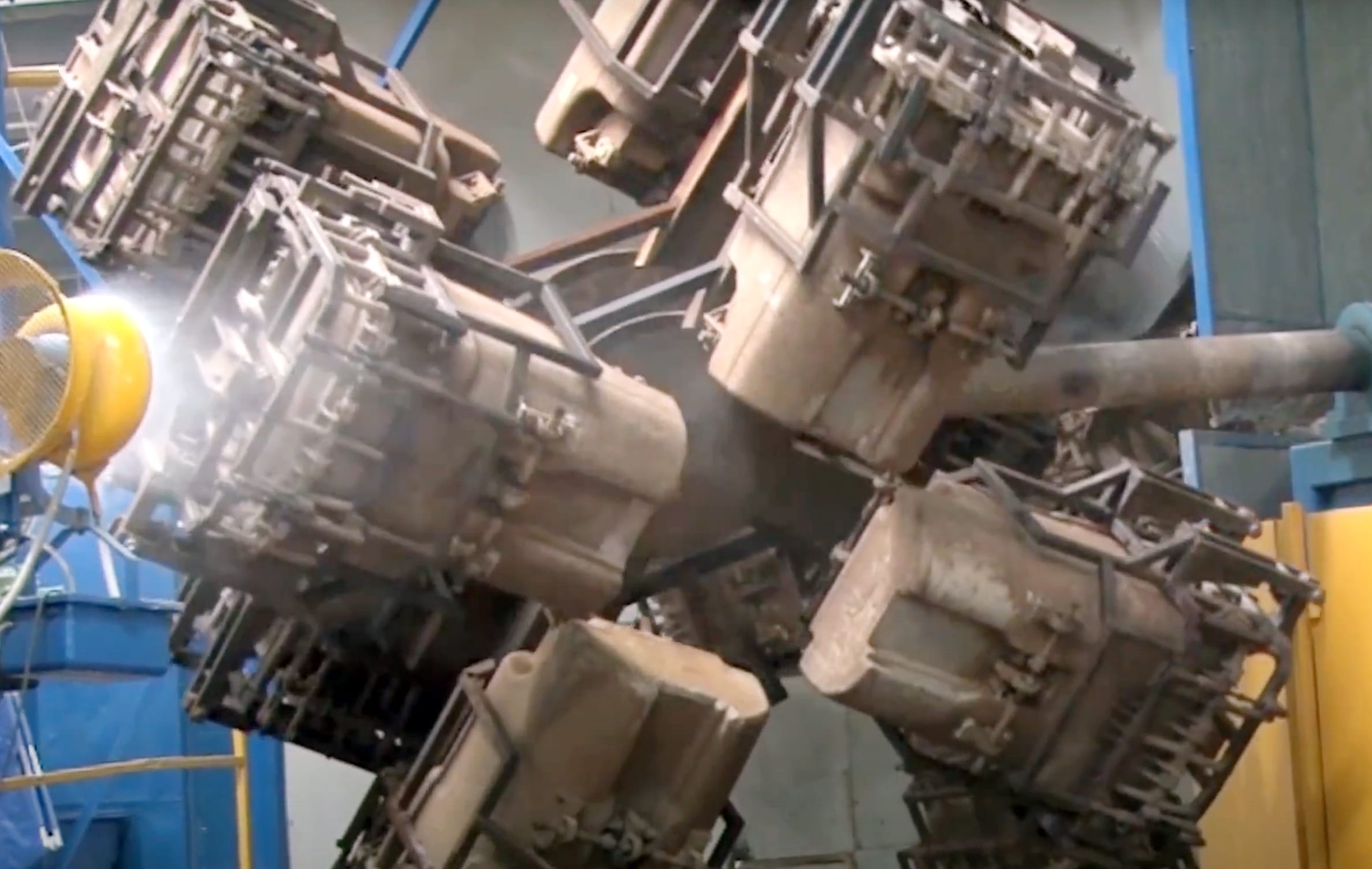

How is a tough-as-nails Toter® cart manufactured? It begins with our patented Advanced Rotational Molding™ process. Molds are filled with a pre-measured amount of plastic micro-pellets, and then moved into an oven where a microprocessor controls the temperature, blower velocity, bi-axial rotation and molding cycle.

The oven melts the plastic material while the machine rotates, allowing the plastic to coat the inside of the mold. This method of heating and molding requires no high-pressure hydraulic equipment to fill the mold, so no stress is introduced during the molding cycle. This is not the case, by the way, with injection-molded products.

The mold is then transferred to the cooling chamber for curing. The cooling cycle is controlled to optimize the final product’s impact strength and performance. After the molds have been slowly cooled with air and water and the cart has cured to achieve its maximum impact strength and physical properties, the cart is removed from the mold to be trimmed, imprinted and assembled.